This medium-sized manufacturing facility, located in an industrial park that experienced an unexplained shutdown of several adjustable speed drives (ASDs) , wreaking havoc on key process equipment. Each day, at approximately 6 am, the utility-owned PF capacitor kicks on to improve the voltage of inductive loads prevalent in many of the park’s manufacturing facilities. The ASDs are conditioned to anticipate this expected power quality event and are typically able to ride through the problem. So when one of the ASDs closed down and interrupted the continuous stream manufacturing process, the facility manager needed to learn why, correct the problem, and prevent it from happening again.

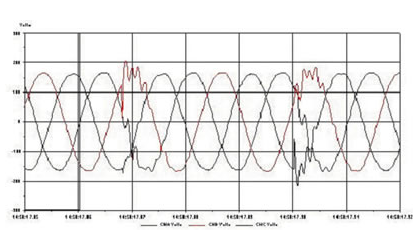

As you can see from the attached screen capture, a second, unanticipated capacitor switching event occurred shortly after the first. This event was categorized by the Signature System Capacitor Switching Answer Module , enabling the facility manager to pinpoint the exact source of the problem. Further analysis showed that the ASD shutdown was the result of an overcurrent trip, which was quickly remedied preventing hours of downtime, at a loss of $10,000/hour.