Major Health Care Center Damaged X-ray Equipment

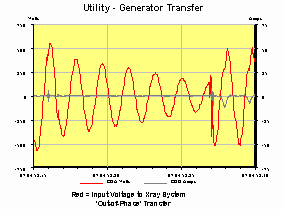

Severe power quality problems damaged Xray equipment, costing $100,000 in one instance. The source of the problem was the switch over from utility to generator power, during regular testing and emergency situations. Figure 1 (below) identified the cause of the problem, an out-of-phase transfer, captured by On Power with a Dranetz 658 Analyzer.

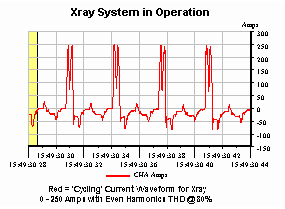

Ideally, an online UPS represents the best solution when protecting against low frequency / high energy events such as >out-of-phase transfers (capacitor bank switching represent similar problems). The challenge was dealing with the size and shape of the inrush currents the Xray demands as it cycles through its program (See Figure 2). Not only did current rise from 20 Amps to 100 Amps (380V system), but even harmonics with a THD of 65% were present. The added challenge was that this Xray procedure represented “invasive” techniques as cathoders are inserted into arteries, sometimes into the heart.

On Power’s solution was based on four phases:

- Extensive Xray system monitoring,

- Solution Research/Simulation,

- Post System Installation Monitoring, and

- Permanently installed Power Quality Monitoring with communication ability. By injecting current to compensate for the distorted waveform, the AIM Filter not only improves the quality of power to the Xray, it lowers the stress on the UPS, lowers impedance placed on the system by the UPS, and improves the output THD to the rest of the systems distribution (See Figure 3).